hysteresis loss for fuel-saving automobile

Jun Liu, Zijian Zheng, Fanzhu Li, Weiwei Lei, Yangyang Gao, Youping Wu, Liqun Zhang, Zhong Lin Wang

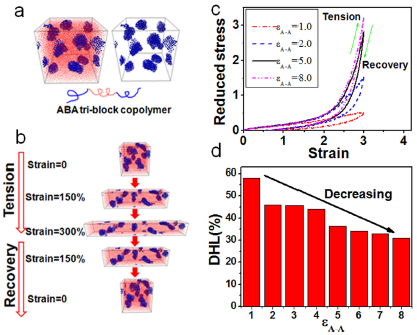

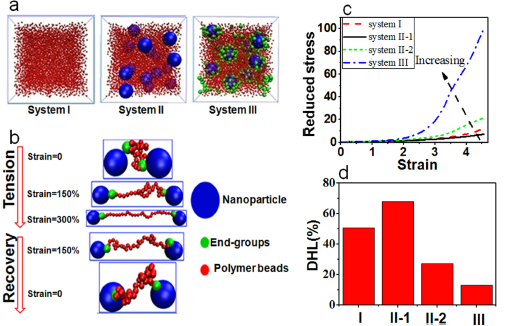

Achieving energy sustainability has imposed a great challenge to improve fuel efficient vehicles. Tires, to overcome the rolling resistance, are responsible for a rather large fraction of energy consumed by vehicles, and a 10% reduction in the rolling resistance corresponds to a 2% decline in the fuel consumption, which, for instance, would save 1–2 billion gallon of fuel per year consumed by the entire passenger vehicle fleet in the United States. From the materials’ perspective, the key bottleneck to lower the rolling resistance of tires lies in designing a novel kind of advanced elastomeric polymer nanocomposites tailored for tire tread, with remarkably low dynamic hysteresis loss (DHL). Here we show that, a nanoparticle chemically end-linking elastomer network, with nanoparticles (NPs) acting as netpoints to chemically connect the dual end-groups of each polymer chain to form a network, exhibits excellent static and dynamic mechanical properties of super-low DHL. The DHL is reduced for ~50% compared to silica NPs filled elastomer that is conventionally used for tire tread. By taking advantage of a library of other nanomaterials such as functionalized carbon nanotube and graphene, our approach provides a versatile framework to fabricate the fuel-saving tires, opening up valuable opportunities for large-scale industrial applications of these nanomaterials in the tire industry.