Abstract:Melt or solution electrospinning are effective and direct techniques for producing nanoscale fibers. Polypropylene (PP) cannot be easily dissolved at ambient temperature. Thus, it is commonly electrospun in the melt state. However, compared with solution electrospun fibers, melt electrospun PP fibers are more uneven and with larger diameters. In this study, to remedy this problem, polar additives, namely stearic acid and sodium stearate, were added into pure PP. The effects of the additives were investigated. The results showed that in contrast to those of pure PP, the fiber diameter of PP with 8 wt. % stearic acid was decreased by 69.3 % (from 5.4 to 1.6 μm). The **allest fiber diameter was 600 nm and the **allest average fiber diameter was 1.8 μm when the sodium stearate contents were 10 and 8 wt. %, respectively. The addition of polar compounds altered not only the diameters of PP microfibers, but also the distribution of diameters, the processing current, and even the thermal properties of the fibers. The microco**ic mechani**s for these changes were interpreted.

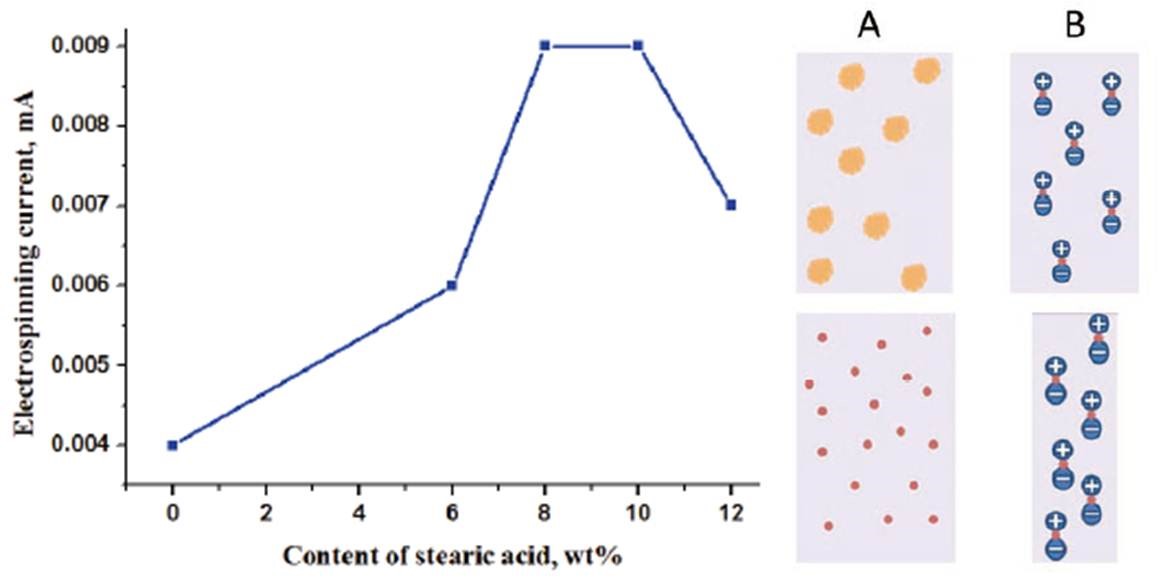

Fig. 1. Changes in the electrospinning current of PP containing different contents of stearic acid and Mimic diagrams of different PP fibers containing additives. The dark rectangles represent fibers. A shows the PP fibers with sodium stearate (irregular particles) (upper) and with stearic acid (points) (lower). B shows the PP fibers with stearic acid (dipole) electrospun at low (upper) and high (lower) voltages.

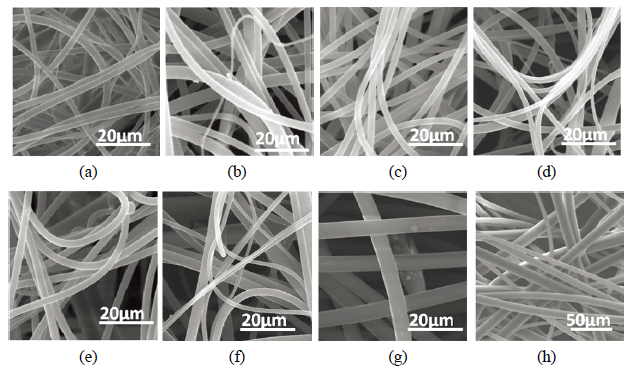

Fig. 2. SEM images of PP fibers containing different contents of additive, electrospun at 220

°C, 10 cm spinning distance, and 30 kV. a) 6 wt. % stearic acid; b) 6 wt. % sodium stearate; c)

8 wt. % stearic acid; d) 8 wt, % sodium stearate; e) 10 wt. % stearic acid; f) 10 wt. % sodium

stearate; g) 12 wt. % stearic acid; h) without additives.