Pulsed Electric Fields on Poly-L-(lactic acid) Melt Electrospun Fibers

G. Xie, Y. Wang, X. Han, Y. Gong, J. Wang, J. Zhang, D. Deng, Y. Liu*

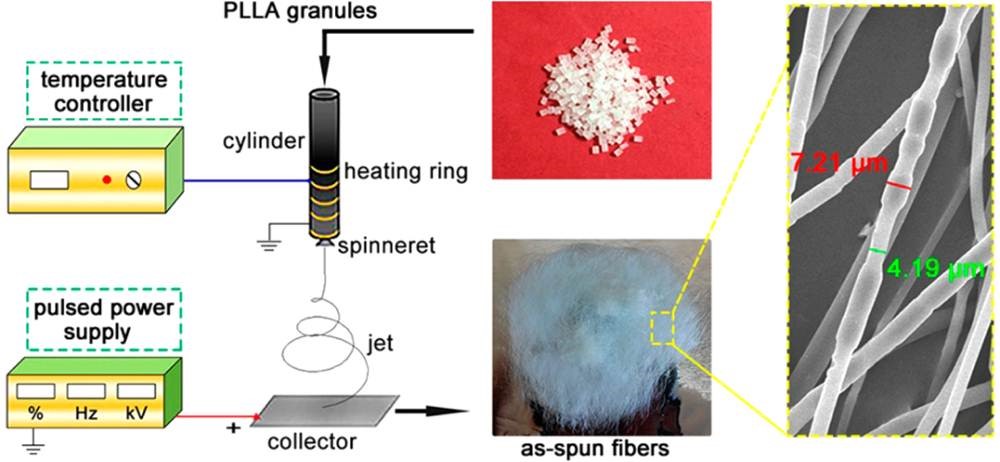

Abstract:In order to overcome the difficulty of reducing fiber diameters during melt electrospinning, a pulsed electric field is applied. The effect of the frequency and duty cycle of the pulsed electric field on the fiber diameter, crystallinity, and molecular orientation was studied. Results revealed that the diameter of the poly-L-(lactic acid) (PLLA) melt electrospun fiber was reduced by this pulsed electric field, especially at

higher frequencies, and the finest fiber was obtained at a duty cycle of 29.8% and a frequency of 1 kHz. Both constant and pulsed electric fields can lead to a high molecular orientation in electrospun fibers, particularly in the crystalline regions. In addition, the molecular orientation and crystallinity of the fibers can also be improved by increasing the frequency and duty cycle of the pulsed power. Of note, fibers with multiple necking structures were interestingly observed at field frequencies of 8 and 10 kHz at the microfiber scale.

TOC

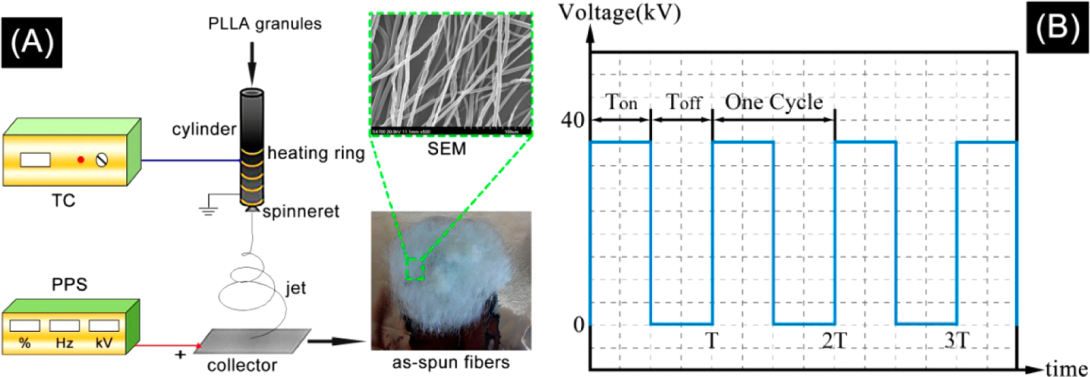

Figure 1. (A) Schematic diagram of the experimental procedure: TC represents temperature controller, and PPS represents pulsed power supply. (B) Schematic diagram of the output voltage waveform signal (blue straight line) of the pulse power supply. T represents the cycle. Frequency is equal to 1/(Ton + Toff). Duty cycle is equal to Ton/Toff.