Solution electrospinning with a pulsed electric field

Kaili Li, Ying Wang, Gai Xie, Jingxin Kang, Hong He, Kejian Wang, Yong Liu*

Abstract:Getting finer fibers is one important goal of electrospinning. In this article, we introduce orthogonal experimental research of solution electrospinning with a pulsed electric field. The influences of the voltage, flow rate, frequency, and duty cycle on the mean diameter and diameter distribution of electrospun fibers were investigated. The phenomenon of electrospinning in a pulsed electric field was compared to that of electrospinning in an ordinary electric field. We found that the order of the factors that affected the fiber diameter was Duty cycle>Flow rate>Voltage>Frequency and the order of factors that affected the fiber diameter distribution was Duty cycle>Flow rate>Frequency>Voltage. In addition, compared with the ordinary electric field, the pulsed electric field apparently contributed to reductions in the mean fiber diameter and diameter distribution. In this article, we provide important evidence for the reduction of the fiber diameter with the pulsed electric field.

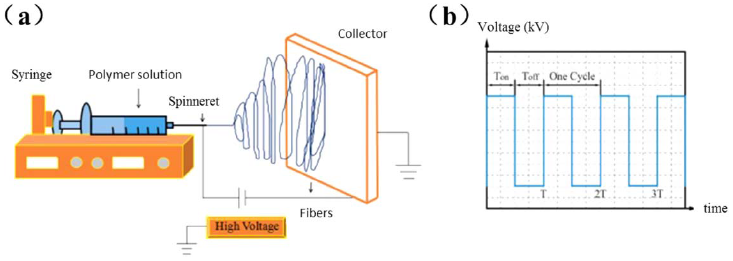

Figure 1. Schematic diagram of the (a) solution electrospinning process and (b) output waveform signal (straight blue line) of the pulse power supply. 2T means the 2nd cycles; 3T means the 3rd cycles.

Figure 2. SEM images of fibers in the orthogonal experiment.