PLLA-PHB fiber membranes obtained by solvent-free electrospinning for short-time drug delivery

K. Cao, Y. Liu*, A. A. Olkhov, V. Siracusa, A. L. Iordanskii

Abstract:Fibers of poly(L-lactic acid) (PLLA)/polyhydroxybutyrate (PHB) with different concentrations of the drug dipyridamole (DPD) were prepared using solvent-free melt electrospinning to obtain a polymeric drug delivery system. The electrospun fibers were morphologically, structurally, thermally, and dynamically characterized. Crazes that resemble lotus root crevices were interestingly observed in the 7:3 PLLA/PHB fibers with 1% DPD. The crystallinity of PLLA slightly decreased as PHB was incorporated, and the addition of DPD significantly reduced the melting temperature of the composite. The interactions between PLLA and PHB mainly occurred at a proportion of 7:3, and drug encapsulation in the fibers was verified. The kinetic profiles of drug release demonstrated the predominant multiple patterns involving a diffusional stage in the short-term mode of release and kinetic process related to the hydrolysis of the biopolymers. Furthermore, the dynamic behavior of the polymer molecules was evaluated based on the segmental mobility using probe electron spin resonance spectroscopy. The segmental mobility in the amorphous fraction of PLLA decreased with increasing PLLA content. The 9:1 PLLA/PHB system was more resistant to polymer hydrolysis than to the 7:3 system and the rate of diffusion transport was approximately two times higher for the 7:3 PLLA/PHB fibers than for the 9:1 PLLA/PHB fibers.

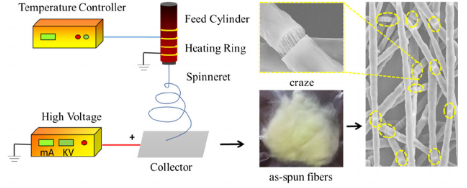

Fig. 1 Schematic diagram of theexperimental devices and the as-spun PLLA/PHB fibers of 7:3with 1% DPD

Fig. 2 (A) Kinetic profiles of drug release from PLLA/PHB mats. (B) Diffusion impact upon the drug controlled release (DPD). Kinetic curves reflect drug diffusivity in the polymer phase