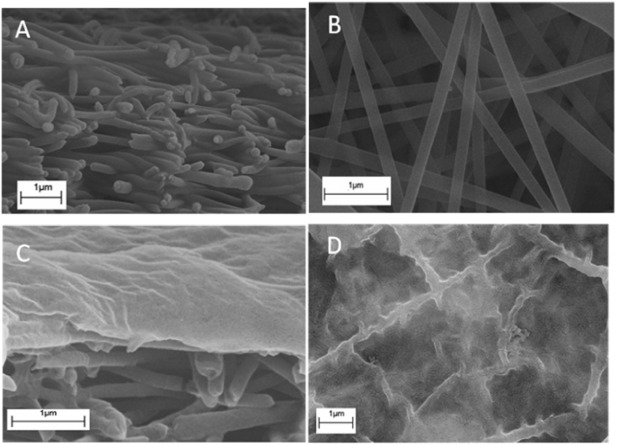

Interfacial polymerization of m-phenylenediamine (MPD) and trimesoyl chloride (TMC) was carried out on top of the highly permeable nanofibrous ultrafiltration (UF) membrane substrates to create thin-film nanofibrous composite (TFNC) reverse o**osis (RO) membranes for desalination. The UF substrates contained distinct fibrous layers: poly(ethylene terephthalate) (PET) non-woven mat as the mechanical support, electrospun polyacrylonitrile (PAN) nanofibrous scaffold as the mid-layer or barrier layer, and ultra-fine cellulose nanofibers (CNs) as the barrier layer. An aliphatic co-monomer, piperazine (PIP) and different additives (e.g. an ionic liquid 1-octyl-3-methylimidazolium chloride, OMIC) were included in interfacial polymerization to improve the permeation flux for RO operations. To further increase the membrane permeability, a spray coating method was also used to control the barrier layer thickness by adjusting the load of the aqueous solutionin polymerization. The optimized RO membrane exhibited a rejection ratio of 96.5% against NaCl (500 ppm) and a flux of 28.6 L/m2 h at 0.7 MPa, approaching the performance of a high-flux commercial RO membrane (DOW FILMTEC™ XLE). We believe higher permeation flux can be achieved using nanocomposite barrier layer with the CN-based UF substrate, while still maintaining high salt rejection ratio.