Composites Part B: Engineering 2016, 98, 134-140

Fang-Lan Guan, Chen-Xi Gui,Hao-Bin Zhang*, Zhi-Guo Jiang, Yue Jiang, Zhong-Zhen Yu*.

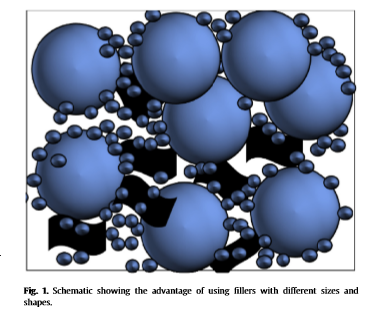

Thermally conductive epoxy composites with eco-friendly flame retardancy are prepared by using spherical alumina (Al2O3),magnesium hydroxide and graphene nanoplatelets (GNPs) as thermally conductive fillers. Highly filled alumina particles do not seriously increase the viscosity of the epoxy monomer due to their spherical shape and **ooth surface and thus the compounding keeps a good processibility; The incorporation of **all amounts of layered GNPs efficiently increases the thermal conductivity of epoxy/Al2O3 composites because of the synergistic effect between layered GNPs and spherical Al2O3 on forming a thermally conductive network within epoxy matrix. Interestingly, the addition of a **all amount of eco-friendly magnesium hydroxide endows the thermally conductive epoxy composites with a satisfactory flame retardancy. The epoxy composite with 68% Al2O3, 7% modified GNPs (m-GNPs) and 5% magnesium hydroxide is determined as the optimum composition with a high thermal conductivity of 2.2 W/(mK), 11 times of that of neat epoxy. Its satisfactory flame retardancy is confirmed by the high limiting oxygen index of 39% and UL-94 rating of V-0 with no dripping. The compact, dense and uniform char layers derived from well-disperSed m-GNPs act as efficient barrier layers and contribute to the flame retardant properties of the epoxy composites. (C) 2016 Elsevier Ltd. All rights reserved.