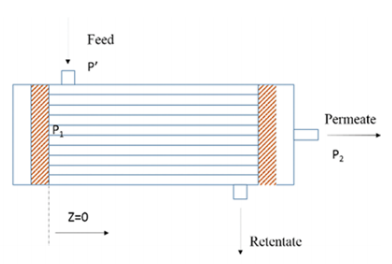

We devised an atmosphere controlling facility to gain a longer life span for mango. A membrane module made of polyethersulfone/polydimethylsiloxane (PES/PDMS) composite membrane was applied to selectively permeate CO2 from the gas mixture of the fruit container. To design the membrane separation system, two models were introduced into our mathematical simulations: (1) an equilibrium model giving the optimal membrane area, the compositions of CO2 and O-2 in the fruit container, feed flow rate and pressures on both the feed and permeate sides of the module, and (2) a dynamic model simulating the change in the gas composition of the fruit container with time. The pressure build-up in the bore side of the hollow fiber was also discussed using the Hagen-Poiseuille equation. The best membrane module configuration was obtained based on the pressure build-up ****ysis. That was (1) the vacuum pressure should be set at 0.1 bar, (2) the hollow fiber inner diameter should be 0.45 mm, and (3) the vacuum should be applied at both ends of the hollow fiber bore sides.