在国内外首次研究开发了在不锈钢表面通过电刷镀大面积制备Pd、Pd-Cu、Cr-Pd、Pd-Co等合金薄膜的工艺技术,使不锈钢在非氧化性腐蚀介质中耐蚀性大幅提高。在Thin Solid Films, Surface and Coatings Technology等刊物上发表系列论文多篇,获授权发明专利3项。

研究开发了针对在用的不锈钢设备进行有效表面处理的技术、镀液循环回收技术和可对大型不锈钢设备表面实施大面积快速电刷镀钯的工艺技术,在PTA企业成功应用,并已列入科技部十二五支撑计划

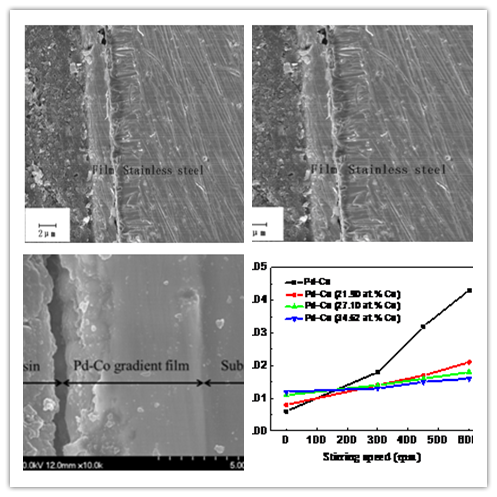

1. 钯合金膜层表面和截面形貌

Pd-Co梯度膜层的耐腐蚀和冲刷性能显著提高

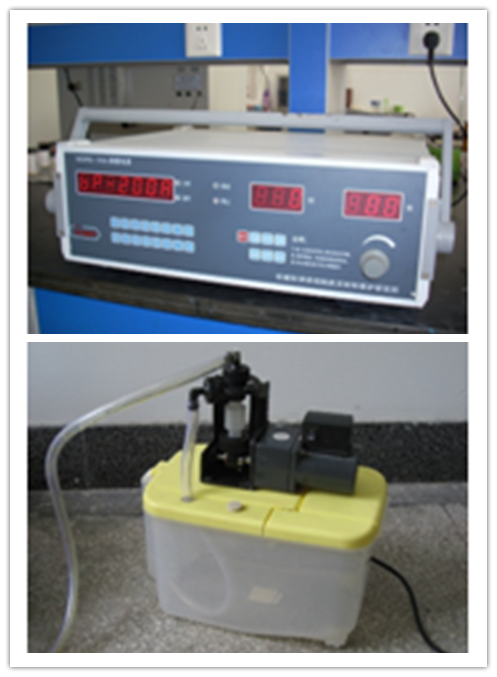

1. 电化学钯合金膜层的典型制备工艺及装备

刷镀电源设备自动给液装置镀液回收装置

所获专利:

文章:

1.Electrodeposition of multi-layer Pd-Ni coatings on 316L stainless steel and their corrosion resistance in hot sulfuric acid solution, Trans. Nonferrous Met. Soc. China, 27 (2017), 1543.

2.Erosion-corrosion behavior of Pd–Co and Pd–Cu films on 316L stainless steel in a simulated PTA slurry environment, Trans. Nonferrous Met. Soc. China, 26 (2016), 167.20172.

3.Electrodeposited Pd-Ni-Mo film as a cathode material for hydrogen evolution reaction, Electrochim. Acta, 174 (2015), 1041.

4. Erosion-corrosion resistance of electroplated Co-Pd film on 316L stainless steel in a hot sulfuric acid slurry environment, Appl. Surf. Sci., 331 (2015), 200.

5.The electroplated Pd-Co alloy film on 316 L stainless steel and the corrosion resistance in boiling acetic acid and formic acid mixture with stirring, Appl. Surf. Sci., 321 (2014), 179.

6.The characteristics of a Pd–Ni/Pd–Cu double coating on 316L stainless steel and the corrosion resistance in stirred boiling acetic and formic acids mixture, Mater. Chem. Phys., 144 (2014), 263.