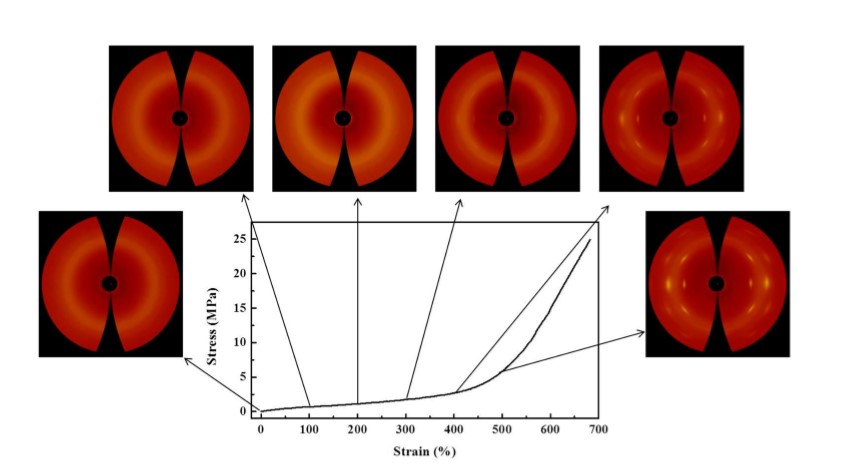

The temperature-induced crystallisation (TIC) and strain-induced crystallisation (SIC) of natural rubber (NR)/isoprene rubber (IR) blends varying in blend ratio were mainly studied by dilatometers and wide-angle X-ray diffraction measurements (WAXD). The dilatometers results showed that the real half-life of crystallisation (t1/2) values of unvulcanised NR/IR blends were 50% less than the theoretical half-life of crystallisation values. From WAXD measurements, the degree of crystallisation of vulcanised NR/IR with IR content samples 30, 50 and 70% at strain 500% were larger than theoretical crystallinity values by 17.17, 19.99 and 29.69%. NR can significantly improve the property of crystallinity of IR during TIC and SIC processes. The results can be ascribed to the end-linked networks existing in NR which can simultaneously induce amorphous NR and IR chains into crystalline order in NR/IR blends and increase the crystallinity and crystallisation rate during TIC and SIC process.