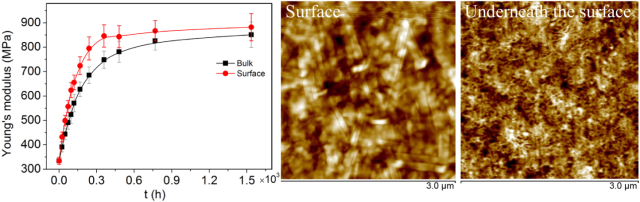

We used atomic force microscopy (AFM) nanomechanical mapping to image the surface of a semicrystalline polymer, specifically polymorphic isotactic poly (1-butene) (iPB), to determine the mechanical properties of a surface layer, and compared this to the properties in the bulk. The measured Young's modulus of the surface layer as a function of annealing time at room temperature was found to be higher than that of the bulk, indicating a more rapid transformation from form II to I polymorphs and an enhanced movement of polymer chain segments at the surface relative to the bulk for this polymer. Plate-like crystals were found at the surface and, as the annealing temperature increased from 70 to 110 °C, evidence of a surface layer was found that increased in thickness from ~30 to ~130 nm, respectively. After removing this layer, the morphology found in the bulk was markedly different. We also used AFM nanothermal ****ysis to determine the local melting point (Tm) and found, that the melting point, Tm, of the crystals at the surface was higher than that of the bulk, in keeping with the modulus measurements. The nanomechanical and nanothermal properties and the morphology at the surface suggest an enhanced movement of polymer chain segments at the surface and therefore, an enhanced crystallization at the surface.